In the realm of industrial applications, the significance of high pressure fittings cannot be overstated. These critical components are essential in ensuring the safe and efficient transport of fluids and gases under high-pressure conditions across various sectors, including oil and gas, chemical processing, and water treatment. According to a report by MarketsandMarkets, the global high pressure fittings market was valued at approximately USD 5.5 billion in 2021 and is projected to reach USD 8.2 billion by 2026, indicating a robust CAGR of around 8.5% during this period. This growth underscores the increasing demand for reliable and durable fittings that can withstand extreme conditions.

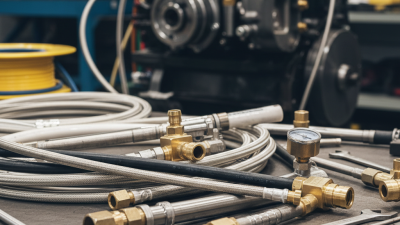

As industries evolve and the technological landscape advances, the variety of high pressure fittings available has expanded significantly. Each fitting type is engineered to meet specific application requirements, enhancing safety, performance, and efficiency. For engineers and procurement specialists, understanding the diverse range of high pressure fittings is crucial. From threaded connections to hydraulic couplings, selecting the right fitting can lead to optimized operation and reduced downtime. The following sections will delve into the top 10 high pressure fittings that are indispensable for any application, empowering professionals with the knowledge needed to make informed decisions in a dynamic industrial environment.

High-pressure fittings play a crucial role in a myriad of industrial applications, ensuring safe and efficient operation across various sectors. These fittings are essential in applications involving the transport of gases, liquids, and other substances under high pressure. Industries such as oil and gas, chemical manufacturing, and aerospace heavily rely on high-pressure fittings to maintain integrity and safety in their systems. The right fitting can significantly reduce the risk of leaks and failures, which could lead to costly downtime or hazardous situations.

Understanding the various types of high-pressure fittings and their specific applications helps in selecting the appropriate component for each unique scenario. For example, in the oil and gas industry, robust fittings are needed to withstand extreme conditions, whereas in medical applications, precision and cleanliness are paramount. In aerospace, weight considerations along with high strength requirements dictate the design and materials used for fittings. Each of these sectors underscores the versatility and importance of high-pressure fittings, highlighting how essential they are to operational success and safety in diverse environments.

When selecting high-pressure fittings, it's crucial to consider both the materials used in their construction and their pressure ratings. Materials determine the strength and durability of the fittings, with common options including stainless steel, carbon steel, and brass. Stainless steel is often favored for its corrosion resistance, making it a suitable choice for harsh environments. On the other hand, carbon steel provides excellent strength at a lower cost, but may require protective coatings to prevent rust in humid or corrosive settings.

Pressure ratings are another key factor, as they indicate the maximum pressure the fittings can handle safely. It's essential to match the fitting's rating with the application's requirements to prevent failures that could lead to leaks or catastrophic failures. Regularly reviewing and understanding the service conditions, such as temperature and fluid type, also assists in making informed choices.

Tips: Always consult industry standards for pressure fittings to ensure compliance and safety. When in doubt, opt for fittings that exceed the required pressure rating for added security. Additionally, consider conducting regular maintenance checks to identify any signs of wear or damage, ensuring the longevity and reliability of your high-pressure systems.

High pressure fittings are critical components in various industrial applications, facilitating the transfer of fluids and gases under significant pressure conditions. The industry standards governing these fittings are essential for ensuring safety, reliability, and performance in systems subjected to high pressure. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) outline specifications that manufacturers must adhere to when producing high pressure fittings. These standards cover material properties, testing methods, and dimensional tolerances, ensuring that fittings can withstand the rigors of their intended applications.

Additionally, compliance with standards such as the American National Standards Institute (ANSI) and the Society of Automotive Engineers (SAE) is crucial for high pressure fittings used in specific industries like oil and gas, aerospace, and automotive. These specifications dictate critical parameters such as pressure rating classifications, temperature limits, and allowable leakage rates. Understanding these industry benchmarks is vital for engineers and designers when selecting the appropriate high pressure fittings for their systems to safeguard operational integrity and enhance safety protocols.

When selecting high-pressure fittings, understanding the pressure ratings associated with various fitting types is crucial for ensuring system integrity and safety. Pressure ratings indicate the maximum pressure a fitting can withstand and are typically classified by material and intended application. For instance, stainless steel fittings often demonstrate higher pressure ratings compared to plastic counterparts, making them suitable for more demanding environments such as chemical processing and oil and gas applications. According to a report by the American Society of Mechanical Engineers (ASME), the standard pressure ratings for fittings can range from 300 psi in low-pressure scenarios to over 10,000 psi in specialized applications.

It's essential to consider how different designs affect pressure retention. For example, welded fittings generally provide superior pressure ratings due to their seamless construction, eliminating potential leak points. Conversely, threaded fittings might offer lower ratings because of the inherent risk of over-tightening or mechanical failure at connection points. The Society of Petroleum Engineers advises engineers to carefully evaluate these variables when designing systems to prevent catastrophic failures.

Tips: Always consult pressure rating charts specific to the materials and types of fittings you are using. Regularly inspect your fittings for signs of wear or damage, as even minor degradation can significantly lower pressure tolerance. Lastly, consider incorporating pressure relief systems as an added safety measure to protect against the risks of overpressure scenarios.

Maintaining high pressure fittings is crucial to ensure their longevity and safe operation in various applications. Regular inspections should be carried out to check for signs of wear, corrosion, or damage. It is essential to verify that all connections are secure and free from leaks. Additionally, ensure that the materials used are compatible with the fluids being transported to prevent any adverse reactions that might compromise safety.

Tips: Always use appropriate protective equipment when handling high pressure systems. This includes gloves and goggles to safeguard against accidental leaks. Ensure training is provided for all personnel to familiarize them with the specific requirements and risks associated with the fittings they will be working with.

Safety practices extend beyond regular inspections. Implementing a proper maintenance schedule can help in identifying potential issues before they escalate into serious problems. It is advisable to document the condition and service history of all fittings, ensuring that any replaceable parts are kept on hand. Regularly educating your team on the latest safety protocols and maintenance techniques can vastly improve overall safety standards in your workplace.

Tips: Consider using pressure relief valves to mitigate the risks involved in high pressure systems. These can be instrumental in preventing accidents if pressure levels exceed the designed parameters.