When it comes to maintaining machinery and equipment, the often-overlooked but crucial component is the grease fitting tool. These simple yet effective devices play a vital role in ensuring that mechanical systems remain lubricated and functioning optimally, reducing wear and tear, and extending the life of your tools and machinery. In this article, we will explore the top 10 best grease fitting tools available on the market, designed to make maintenance and repairs easier than ever before.

Understanding the importance of regular greasing can significantly enhance operational efficiency and decrease the likelihood of costly downtimes. Without proper lubrication, machine components can suffer from friction and excessive heat, leading to breakdowns that could have been easily prevented. Our comprehensive guide will delve into the features, benefits, and unique functionalities of each grease fitting tool, equipping you with the knowledge needed to select the right one for your specific maintenance needs. Whether you're a professional mechanic or a DIY enthusiast, this article aims to provide you with valuable insights that will help streamline your lubrication tasks and ensure your equipment remains in peak condition.

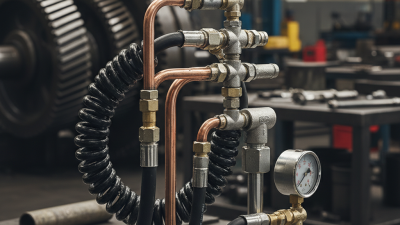

Grease fittings play a crucial role in the maintenance of machinery and equipment, ensuring longevity and optimal performance. These small but significant components allow for easy lubrication of moving parts, reducing friction and wear over time. Proper lubrication is essential as it prevents overheating and damage, which can lead to costly repairs and downtime. Understanding the function of grease fittings can save operators significant time and resources by facilitating regular maintenance routines.

Incorporating the right tools for grease fitting maintenance is vital for ensuring that these fittings remain accessible and functional. Tools designed specifically for grease fittings enable users to quickly apply lubricant without making a mess or wasting product. Regular maintenance, including the use of appropriate grease fitting tools, not only enhances performance but also extends the life of valuable machinery. By developing a routine around checking and maintaining grease fittings, businesses can minimize unexpected failures and maintain optimal operational efficiency.

When it comes to maintaining machinery, having the right grease fitting tools is essential for ensuring the longevity and efficiency of your equipment. Grease fittings, often found in heavy machinery and vehicles, allow for easy lubrication to reduce friction and wear. Understanding the different types of grease fitting tools is pivotal for anyone involved in maintenance and repairs.

There are several common options available, each designed for specific tasks. A grease gun is perhaps the most essential tool, providing controlled application of grease under pressure, which is vital for reaching hard-to-access fittings. Another indispensable tool is the grease fitting cleaner, which ensures that grease fittings remain unobstructed for effective lubrication. Furthermore, specialty adapters can be used to connect various hose sizes to different fitting configurations, allowing for more versatility in operation. According to industry reports, proper maintenance using these tools can extend the life of machinery components by up to 50%, minimizing downtime and repair costs.

Tips for effective use of grease fitting tools include regularly inspecting all fittings for debris or damage and ensuring that you are using the correct grease type recommended for your specific machine or vehicle. Always keep your grease gun clean and well-maintained to prevent contamination of the lubricants. Additionally, following a regular maintenance schedule will facilitate smoother operation and enhance the overall performance of your equipment. By utilizing the right tools and techniques, you can achieve optimal maintenance results.

When selecting grease fitting tools for maintenance and repairs, there are several key features that should be prioritized to ensure efficiency and effectiveness. One of the most critical factors is the compatibility of the tool with various grease fitting sizes; tools that offer a range of sizes can handle the diverse needs of machinery and equipment. According to industry studies, having the right tool size can increase lubrication efficiency by up to 30%, thereby extending the life of your equipment.

Another important feature to consider is the build quality of the grease fitting tools. Tools made from high-quality materials such as steel or heavy-duty alloys tend to last longer and resist wear and tear better than their counterparts. A report from the Machinery Lubrication Association indicates that using durable tools can significantly reduce downtime associated with maintenance tasks, leading to increased productivity and lower operational costs. Additionally, ergonomic designs can enhance user experience, enabling mechanics to work comfortably for extended periods, thus reducing the risk of repetitive strain injuries.

Lastly, ease of use and maintenance should not be overlooked. Grease fitting tools with automated grease delivery systems or nozzles that provide a better fit can drastically decrease the time needed for lubrication tasks. Research from the International Maintenance Institute shows that improving lubrication practices through user-friendly tools can lead to a 45% reduction in equipment failure rates. By focusing on these key features, you can ensure that your grease fitting tools will provide reliable performance for all your maintenance needs.

| Tool Name | Type | Material | Size | Key Features |

|---|---|---|---|---|

| Grease Gun | Manual/Electric | Steel/Aluminum | 12 oz | High pressure, Flexible hose |

| Grease Injector Tool | Pneumatic | Plastic/Steel | N/A | Easy one-handed operation, Stable grip |

| Grease Fitting Cleaner | Manual | Metal | N/A | Removes blockages, Simple design |

| Fitting Wrench | Hand Tool | Chrome Vanadium | 8-19 mm | Durable, Non-slip handle |

| Grease Coupler | Attachment | Steel | Standard | Quick connect, Leak-proof |

| Grease Fitting Set | Kit | Steel | Various | Multiple sizes, Storage case |

| Portable Grease Pump | Manual | Aluminum | 5 gallons | High capacity, Easy transport |

| Pressure Gauge Adapter | Accessory | Brass | N/A | Pressure readings, Easy installation |

| Grease Applicator | Hand Tool | Plastic/Metal | N/A | Precision, Comfortable grip |

| Grease Migration Eliminator | Specialty Tool | Rubber/Plastic | N/A | Prevents grease leaks, Easy to use |

Proper use of grease fitting tools is essential for effective maintenance and repairs in a variety of machinery. To begin, ensure you have the right type of grease fitting tool for the specific application. Commonly used tools include grease guns, adaptors, and extension hoses, which help deliver lubricant evenly and thoroughly. Before starting, inspect the grease fittings to confirm that they are clean and free of debris, as dirt can contaminate the grease and potentially damage your machinery.

When applying grease, it's crucial to use the correct technique. Position the grease fitting tool securely against the fitting, and apply consistent pressure to dispense the lubricant. Avoid over-greasing, as this can cause excess grease to leak out and create a mess, or even lead to seal damage. Monitor the pressure to ensure the grease is being injected smoothly, and periodically check for any resistance that may indicate a blockage in the fitting. By following these guidelines, you can maintain the longevity and efficiency of your equipment with ease.

This chart represents the effectiveness rating of the top 10 grease fitting tools based on user feedback. The effectiveness is measured on a scale from 1 to 10, where 10 indicates the highest effectiveness for maintenance and repairs.

When it comes to maintaining and repairing machinery or vehicles, having the right grease fitting tools is essential. These tools ensure that lubrication is applied efficiently, which can prolong the life of components and prevent costly failures. Among the top brands offering exceptional grease fitting tools, you’ll find products that are engineered for durability and ease of use, making them a staple in any mechanic's toolkit.

Look for tools that feature ergonomic designs, enabling a comfortable grip during prolonged usage. This can significantly enhance the efficiency of maintenance tasks. Additionally, consider those with interchangeable nozzles and attachments, which provide versatility for accessing hard-to-reach fittings. Reliable materials, such as high-strength metals and corrosion-resistant finishes, are also a hallmark of quality grease fitting tools, ensuring they withstand the demands of continuous use in various environments. Investing in well-crafted tools not only facilitates easy maintenance but also promotes a proactive approach to machine care, ultimately saving time and reducing repair costs.