In the world of industrial maintenance and automotive repair, the air grease pump has emerged as an indispensable tool. Renowned expert in lubrication technology, Dr. Emily Rivers, states, "An air grease pump not only enhances efficiency but also ensures precision in the application of grease, minimizing waste and maximizing performance." This powerful device operates on a pneumatic mechanism, allowing users to deliver grease with ease and accuracy, making it a favored choice among mechanics and engineers alike.

As we dive deeper into the working principles and advantages of an air grease pump, it is essential to understand that its design caters to high-demand environments, ensuring that equipment remains well-lubricated and operational. With its ability to stream large quantities of grease quickly, the air grease pump significantly reduces downtime in maintenance tasks. The seamless functionality of this tool lies in its sophisticated engineering, which is tailored to meet the diverse needs of various industries, therefore playing a crucial role in equipment longevity and reliability.

By gaining insights into the mechanics, uses, and benefits of air grease pumps, professionals can better appreciate how this innovative tool supports their daily operations. In the following sections, we will explore the intricacies of its design and the reasons behind its growing popularity in workshops and manufacturing facilities around the globe.

An air grease pump is a crucial tool in various industries, particularly in the automotive and manufacturing sectors. This device uses compressed air to deliver grease efficiently and effectively, ensuring that machinery and components remain lubricated. It primarily functions by converting compressed air into mechanical energy, which drives a piston that discharges grease through a nozzle or a series of hoses. This mechanism allows for the rapid application of lubricant, enhancing the efficiency of maintenance tasks.

According to a report by Research and Markets, the global air grease pump market is expected to experience significant growth, driven by the increasing demand for automation and maintenance in industrial settings. The report indicates that the market is forecasted to grow at a compound annual growth rate (CAGR) of 5.2% from 2021 to 2026. This growth reflects the essential role that air grease pumps play in reducing downtime and extending the life of machinery by ensuring consistent lubrication. Moreover, air grease pumps offer the advantage of portability and ease of use, making them a preferred choice for technicians and maintenance professionals across various applications.

An air grease pump is an essential tool used in various industrial and automotive applications for delivering grease to hard-to-reach areas. Understanding the key components of an air grease pump is crucial to optimizing its performance and ensuring efficient lubrication processes.

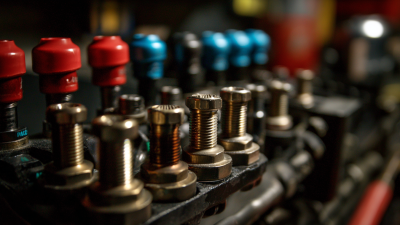

The primary components of an air grease pump include the pump housing, which contains the internal mechanics; a pneumatic motor, which generates the pressure needed for grease delivery; and the grease reservoir, where the lubricant is stored before being dispensed. Additionally, there are hoses that carry the grease to the desired location and nozzles designed for precise application. Each of these components plays a vital role in the pump’s functionality, allowing it to operate smoothly and effectively under varying work conditions.

Tips: Regular maintenance is crucial for air grease pumps. Ensure the hoses and nozzles are clear of any blockages to maintain optimal flow. Also, check the pneumatic motor for air leaks that could compromise performance. By keeping these components in good condition, you can maximize the lifespan of your pump and improve its reliability in your operations.

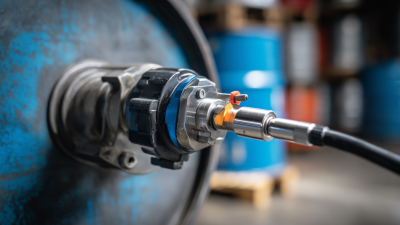

An air grease pump operates using compressed air to efficiently dispense grease into machinery and equipment. The fundamental mechanism involves an air motor that drives a gear system, which in turn pushes a grease piston. When compressed air enters the pump, it activates the air motor, causing the piston to move forward and create pressure in the grease chamber. This pressure forces the grease out of the pump through a hose and nozzle, allowing for precise application in hard-to-reach areas.

The design of an air grease pump allows for continuous grease flow without manual effort, making it particularly useful in industrial environments. The piston stroke can be adjusted, providing control over the volume of grease dispensed per cycle.

Moreover, the pump's use of air pressure reduces the risk of over-lubrication, ensuring that machinery receives the right amount of grease for optimal performance. This system not only improves efficiency in maintenance operations but also enhances the longevity of equipment by ensuring consistent lubrication.

Air grease pumps are crucial tools in various industries that require efficient lubrication for machinery and equipment. Their applications span across automotive, manufacturing, and construction sectors, where they help ensure the smooth operation of machines by delivering grease under pressure. According to recent industry reports, the global air grease pump market is expected to grow at a CAGR of approximately 5% over the next few years, driven by the increasing demand for maintenance in industrial operations.

In the automotive sector, air grease pumps are frequently used to lubricate vehicle components, such as wheel bearings, chassis, and driveline components. Their ability to dispense grease quickly and efficiently reduces downtime, enhancing productivity. The manufacturing industry also benefits from these pumps, particularly in assembly lines where machinery operates continuously. Research indicates that businesses employing air grease pumps can reduce maintenance costs by up to 20% due to their precision and reliability in lubricating parts that would otherwise wear down quickly.

Additionally, in the construction industry, air grease pumps are employed to maintain heavy machinery like excavators and bulldozers, preventing excessive wear and tear during grinding operations. The ability to operate in extreme conditions further solidifies their importance, as equipment frequently exposed to dirt and debris greatly benefits from regular and thorough lubrication. Overall, the versatility and efficiency of air grease pumps make them indispensable in enhancing the longevity and performance of equipment across various fields.

Air grease pumps have become essential tools across various industries, primarily due to their ability to enhance efficiency and precision in lubrication processes. By utilizing compressed air, these pumps deliver grease systematically and consistently, reducing the effort and time required for manual lubrication. This is particularly advantageous in manufacturing and automotive environments, where machinery and equipment must be well-maintained to prevent breakdowns and ensure optimal performance. The ability to apply lubrication evenly also helps in minimizing wear and tear, thereby extending the lifespan of components.

In addition to improving maintenance protocols, air grease pumps contribute to workplace safety and hygiene. Manual grease applications can be messy and hazardous, but with air-operated systems, the risk of spills is significantly reduced. Workers can enjoy a cleaner work environment while minimizing their exposure to potentially harmful substances. Furthermore, these pumps allow for the automation of lubrication tasks, enabling workers to focus on more critical responsibilities. As industries continue to prioritize efficiency, safety, and reliability, the adoption of air grease pumps is likely to expand, driving innovations in lubrication technology across sectors.