In the realm of machinery maintenance, understanding the appropriate "grease fitting sizes" is crucial for ensuring optimal performance and longevity of equipment. As machinery expert John Smith once noted, "Selecting the right grease fitting sizes can significantly reduce downtime and maintenance costs." This statement underscores the importance of precision in maintenance practices, particularly when it comes to the often-overlooked details such as grease fittings.

Grease fittings, also known as Zerk fittings, are vital components that facilitate the lubrication of machinery by allowing grease to be injected into bearings and joints. However, with various sizes available, it becomes imperative for technicians and maintenance managers to choose the correct fitting size to avoid complications like grease leakage or insufficient lubrication. In this guide, we will explore the most common grease fitting sizes used in the industry, provide insights into their specific applications, and highlight best practices for maintenance to achieve peak performance and efficiency.

By equipping yourself with the knowledge of grease fitting sizes, you can ensure that your equipment remains well-lubricated, thereby extending its lifespan and improving operational reliability. Join us as we delve deeper into the intricacies of grease fitting sizes and their role in effective maintenance strategies.

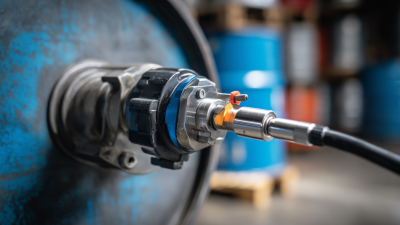

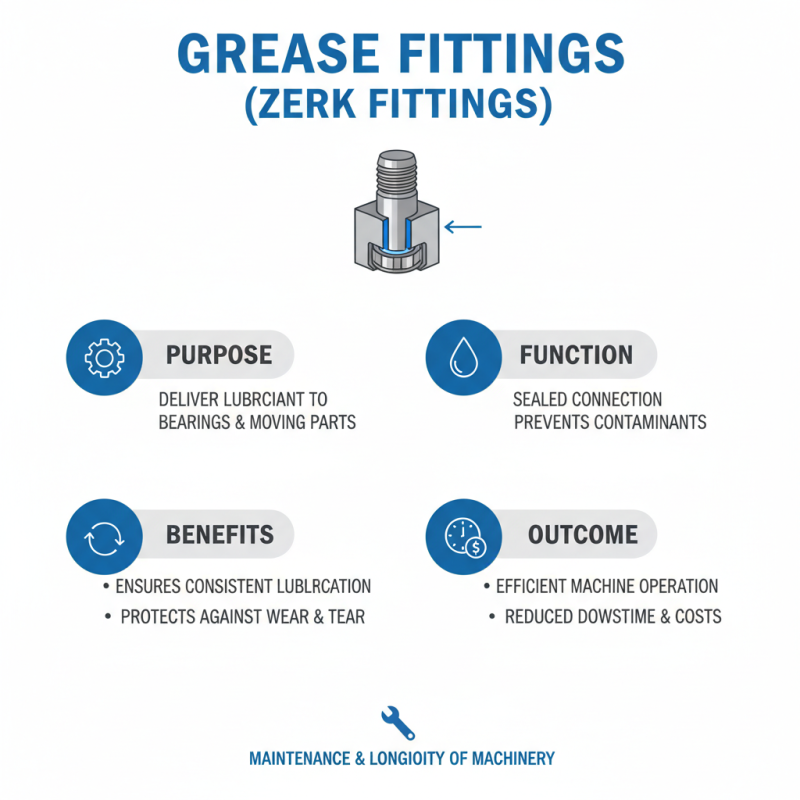

Grease fittings, often referred to as Zerk fittings, play a crucial role in the maintenance and longevity of machinery. Their primary purpose is to provide a convenient way to deliver lubricant directly into bearings and other moving parts that require regular lubrication. This sealed connection prevents contaminants from entering, ensuring that the internal components remain lubricated and protected against wear and tear. By facilitating a consistent flow of grease, these fittings ensure that machinery operates efficiently, reducing downtime and maintenance costs.

Understanding the significance of grease fittings is essential for anyone involved in equipment upkeep. The correct fitting size and type can greatly influence the effectiveness of lubrication, which in turn affects the overall performance of the machinery. Properly maintained grease fittings help prevent failures caused by friction and overheating, thus extending the lifespan of the equipment. Regular inspection and timely replacement of these fittings ensure optimal maintenance performance, ultimately leading to enhanced operational efficiency and reliability in various industrial applications.

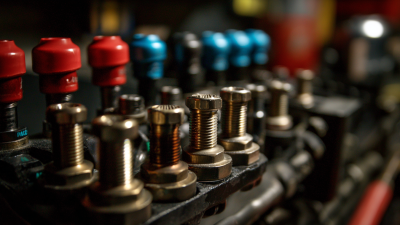

Grease fittings, essential for maintaining machinery and vehicles, come in various types, each designed for specific applications. The most common types include 1/8" NPT, 1/4" NPT, and the metric sizes like M6 and M8. These fittings ensure that grease reaches vital components, reducing wear and extending the lifespan of machinery. Understanding the right type of fitting for your application can significantly enhance maintenance efficiency.

When working with grease fittings, there are a few tips to keep in mind. First, always check the manufacturer's specifications to choose the appropriate fitting size. Using the wrong fitting can lead to leaks or insufficient lubrication. Additionally, ensure that you regularly clean the fittings to prevent dirt and debris from entering, which can compromise the lubrication process.

Moreover, it’s essential to monitor the grease level regularly. Over-greasing can cause seal damage and create unnecessary pressure within the components. Implementing a consistent maintenance schedule based on the machinery's usage will aid in determining when to grease and which fittings to check. By paying attention to these details, you can optimize performance and ensure that your equipment operates smoothly.

This chart displays the most common grease fitting sizes and their respective applications, reflecting the optimal maintenance performance for various machinery.

As we move into 2025, understanding the popular grease fitting sizes is crucial for ensuring optimal maintenance performance across various applications. Grease fittings, or Zerk fittings, are essential components in machinery that require regular lubrication to function efficiently. The most commonly used sizes this year are 1/4-28, 1/8 NPT, and M6, as they cater to a wide range of equipment and vehicle types. These sizes not only facilitate ease of maintenance but also ensure that lubricant is effectively distributed to critical moving parts.

In addition to standard sizes, the demand for specialized grease fittings has also increased. Adapting to specific machinery requirements, sizes like 3/8-24 and 10-32 are gaining popularity for niche applications. These fittings are crucial in industries such as automotive, construction, and manufacturing, where precise lubrication is vital for equipment longevity and performance. Choosing the right grease fitting size can significantly impact the efficiency of maintenance operations, thereby minimizing downtime and enhancing productivity in 2025 and beyond.

Selecting the right grease fitting size is crucial for maintaining optimal performance in machinery. A well-chosen fitting ensures efficient lubrication, prolongs equipment lifespan, and minimizes downtime. When evaluating grease fitting sizes, consider the specific application and grease type. Larger fittings can facilitate faster lubrication but may not always be necessary for smaller components. Always refer to the equipment manufacturer's guidelines to ensure compatibility and effectiveness.

**Tips:** When in doubt about fitting sizes, opt for a selection kit that includes various sizes. This allows for flexibility and ensures that you're prepared for different maintenance tasks. Additionally, regular inspections of grease fittings can prevent clogging and other issues, ensuring that your machinery operates smoothly.

Understanding the threading standards is also essential. Grease fittings come in various thread pitches such as metric and imperial. Always double-check the thread type before purchasing to avoid mismatches. Investing time in selecting the appropriate grease fitting size pays off in the long run by ensuring optimal lubrication and performance for your machinery.

| Fitting Size (Inches) | Recommended Application | Optimal Grease Type | Maintenance Frequency |

|---|---|---|---|

| 1/8 | Small machinery | Lithium-based grease | Every 3 months |

| 1/4 | Automobiles | Calcium sulfonate grease | Every 6 months |

| 3/8 | Heavy equipment | Lithium complex grease | Every 0.5 years |

| 1/2 | Industrial machinery | Synthetic grease | Annually |

| 3/4 | Construction vehicles | Molybdenum disulfide grease | Every 4 months |

Grease fittings play a vital role in ensuring optimal maintenance performance across various machinery and equipment. Regular lubrication is essential for mitigating wear and tear, thus extending the lifespan of components such as automatic slack adjusters. According to industry studies, timely and adequate greasing can reduce mechanical failures by up to 30%. This highlights the necessity of an effective maintenance schedule that prioritizes lubrication.

To achieve optimal maintenance performance with grease fittings, adhere to the following tips: First, establish a consistent greasing schedule tailored to the specific requirements of your equipment. Regular checks and timely interventions are crucial. Second, utilize the correctly sized grease fittings that align with your machinery's specifications to ensure proper lubrication delivery. This small detail can significantly enhance the effectiveness of your maintenance strategy. Lastly, educate your team on the significance of grease management, as it contributes to preventing potential issues caused by inadequate maintenance procedures.

Implementing these practices not only supports longevity and efficiency but also shifts the operational culture towards proactive maintenance strategies, ultimately benefiting overall productivity.