In the realm of maintenance and machinery care, the choice of lubricants can significantly impact performance and longevity. One standout option in this domain is dry moly lube, renowned for its unique properties that cater to a wide array of applications. Unlike conventional lubricants, dry moly lube operates effectively under extreme conditions, offering excellent protection against wear, friction, and corrosion. This remarkable formulation not only provides a superior coating for surfaces but also adheres firmly, ensuring long-lasting performance.

As we explore the top uses and benefits of dry moly lube, it becomes evident how versatile this lubricant is across various industries. From automotive and aerospace to manufacturing and home maintenance, dry moly lube has cemented its reputation as an essential tool for operators seeking efficiency and reliability. Understanding its effectiveness and applications can help users make informed decisions regarding their maintenance needs, ultimately contributing to smoother operations and reduced downtime. Whether you are a seasoned professional or a DIY enthusiast, recognizing the potential of dry moly lube can transform your maintenance strategies and deliver outstanding results.

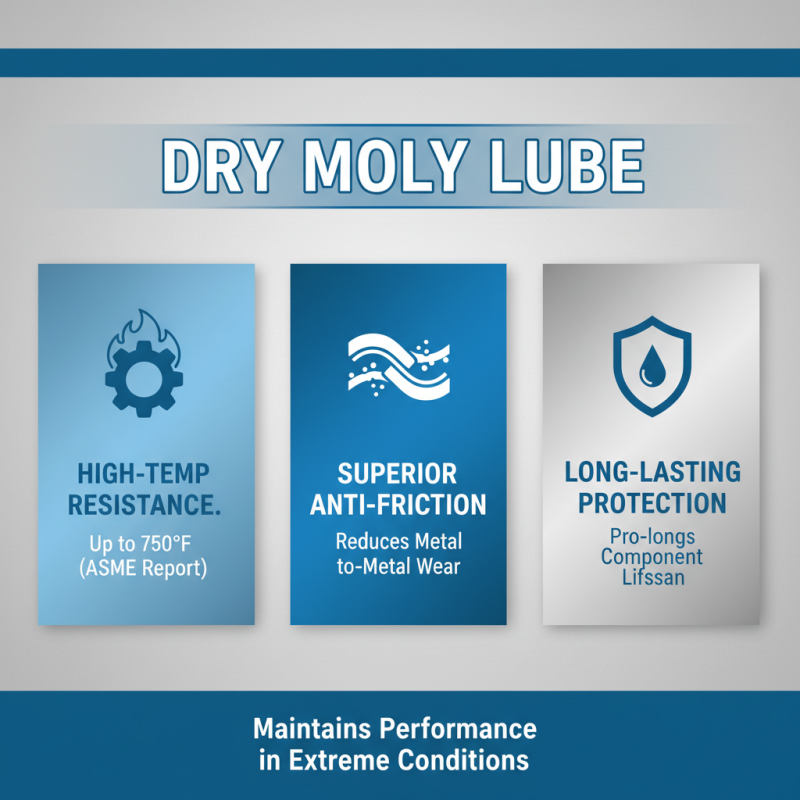

Dry Moly Lube is a specialized lubricant known for its unique properties and composition that make it an ideal choice for various maintenance applications. Comprising primarily of molybdenum disulfide (MoS2), this substance exhibits exceptional anti-friction and load-bearing capabilities. According to a report by the American Society of Mechanical Engineers (ASME), molybdenum disulfide can withstand temperatures up to 750°F, making it suitable for high-temperature environments where conventional greases often fail. The solid particles present in Dry Moly Lube adhere well to surfaces, creating a protective layer that reduces metal-to-metal wear and prolongs the lifespan of mechanical components.

In addition to its thermal stability, Dry Moly Lube is known for its superior resistance to water and other contaminants. This characteristic is crucial as it helps maintain lubrication effectiveness in harsh conditions. A study published in the Journal of Materials Science highlighted that equipment maintained with Dry Moly Lube showed a decrease in friction coefficient by up to 40% compared to those treated with traditional oils. Its dry film lubricant nature prevents dirt accumulation, further enhancing the performance of machinery and reducing maintenance intervals. Thus, understanding the properties and composition of Dry Moly Lube is essential for effectively utilizing its benefits in industrial and maintenance settings.

Dry moly lube, known for its exceptional lubrication properties, has become a crucial asset across various industries. Its primary application lies in areas requiring high-temperature resistance and extreme pressure resilience. According to a report by Machinery Lubrication, dry lubricants like molybdenum disulfide can withstand temperatures up to 750°F (400°C) while maintaining stability, making them ideal for environments where conventional oils might fail. Industries such as aerospace, automotive, and heavy machinery heavily leverage these characteristics, utilizing dry moly lube in applications ranging from engine components to conveyor systems.

Another significant application of dry moly lube is in the food and beverage industry, where lubrication needs to meet stringent hygiene standards. The USDA notes that dry lubricants pose minimal risk of contamination compared to traditional grease and oil lubricants. They are particularly advantageous in high-speed machinery where residue from liquid lubricants can lead to product contamination. By employing dry moly lube, facilities can streamline their maintenance processes while ensuring compliance with safety regulations without compromising operational efficiency.

Moreover, the construction sector benefits from dry moly lube's exceptional load-bearing capacity, often surpassing traditional lubricants. According to a study conducted by the American Society of Mechanical Engineers (ASME), dry lubricants exhibit a lower coefficient of friction and reduce wear significantly, which leads to decreased maintenance costs and extended equipment lifespan. As industries continually seek efficient solutions for maintenance, dry moly lube stands out as a versatile tool to enhance performance while meeting environmental and safety standards.

Dry Moly Lubricant (DML) has become increasingly popular in various industries due to its unique properties and advantages over conventional lubricants. According to the National Lubricating Grease Institute (NLGI), dry lubricants such as Molybdenum disulfide can operate effectively in extreme pressure and temperature conditions, making them indispensable in environments that might degrade traditional oils and greases. For example, DML maintains performance at temperatures ranging from -100°F to 750°F, which allows it to function effectively in high-stress applications such as bearings, chains, and gears where overheating is a concern.

One of the most notable advantages of dry moly lube is its ability to reduce friction without attracting dust and dirt, which is a common issue with wet lubricants. A study published by the Society of Tribologists and Lubrication Engineers (STLE) indicates that using dry lubricants can reduce friction by up to 50% compared to oils and greases, leading to higher efficiency and longer equipment lifespan. Additionally, because DML leaves a dry film on the surfaces it lubricates, it prevents buildup and keeps components cleaner, which is particularly beneficial in food processing and pharmaceutical environments, where cleanliness is paramount. The distinct performance characteristics of dry moly lube thus provide significant advantages over traditional lubricant solutions, making it an ideal choice for diverse maintenance applications.

Dry Moly Lubricant (Dry Moly Lube) has gained recognition in various maintenance applications due to its unique properties and quantitative benefits. Its low friction coefficient (often cited as around 0.1) significantly reduces wear and tear on machinery, enhancing their lifespan. According to a report by the National Lubricating Grease Institute, proper lubrication in maintenance can improve equipment performance by up to 80%, with most failures attributed to inadequate lubrication practices. By incorporating Dry Moly Lube, maintenance teams can achieve not only smoother operations but also considerable cost savings in repair and downtime, which can escalate quickly in industrial settings.

In addition, Dry Moly Lube excels under extreme pressure, making it an excellent choice for heavy-load applications. Studies indicate that the lubricant can withstand load pressures exceeding 100,000 psi without compromising its protective qualities. This characteristic can be crucial in maintenance tasks involving high-stress machinery, as it minimizes metal-to-metal contact, thereby preventing costly damage and extending maintenance intervals.

Tips: When applying Dry Moly Lube, ensure that the surface is clean and free of contaminants to maximize adhesion and effectiveness. Also, consider periodic re-application based on operational demands and environmental conditions to maintain optimal performance. Regular monitoring of lubrication quality can lead to improved operational efficiency and machine reliability.

Dry Moly Lube is gaining traction in various maintenance applications due to its unique properties that enhance performance while reducing environmental impact. Unlike traditional wet lubricants, Dry Moly Lube emits minimal volatile organic compounds (VOCs), making it a safer option for both users and the environment. According to industry studies, the use of dry lubricants can decrease contamination in sensitive settings, such as food processing plants or clean rooms, by minimizing the risk of flammable and harmful byproducts.

When considering the environmental impact of product usage, it’s crucial to recognize that Dry Moly Lube can operate effectively in high-pressure and high-temperature applications while significantly reducing metal-to-metal contact. Reports from the American Society of Mechanical Engineers indicate that employing such lubricants can lead to a reduction in energy consumption by up to 20% as it facilitates smoother machinery operation. This not only extends the lifespan of equipment but also contributes to overall sustainability efforts in maintenance practices.

Tips: When applying Dry Moly Lube, ensure that the surfaces are clean and free from contaminants to optimize adhesion and effectiveness. Additionally, consider using a light application; less can often yield better results, promoting efficiency while minimizing waste. Regularly check for signs of wear on lubricated components to determine when reapplication is necessary, ensuring that maintenance practices remain proactive rather than reactive.